Your road to automotive growth.

Car innovations never cease – they never cease to amaze, and never cease to grow. But, when speed to market for desirable vehicles matters, are you ahead of the competition? The answer lies in Intelligent Automation Systems’ lean supply of integrated motion control products and automation systems. It’s like taking a 3600 drive to get the bigger picture. And, we have the know-how to help you.

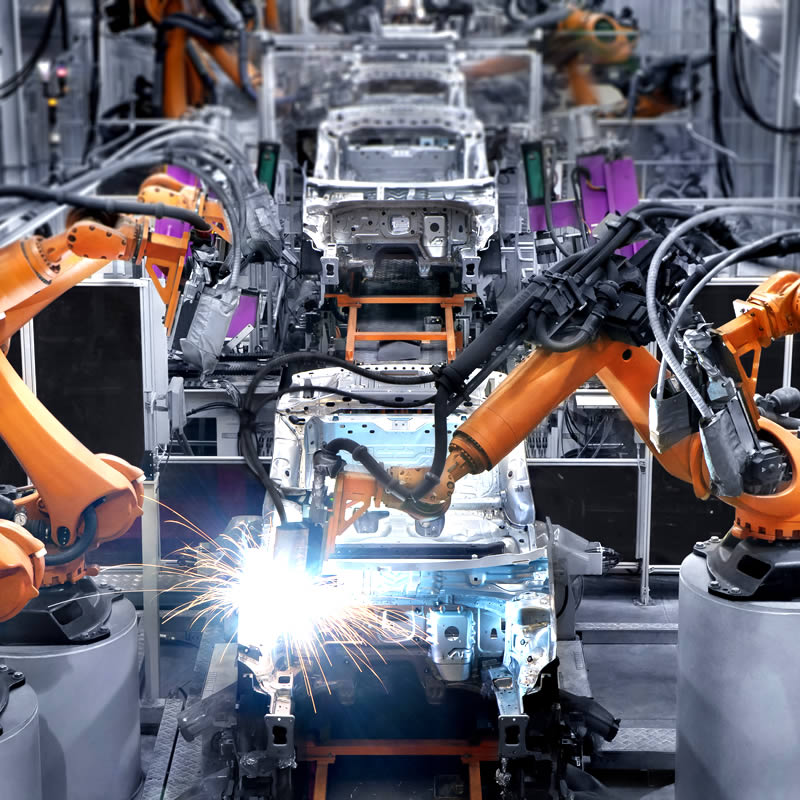

You need reliable materials handling technology, overhead trolley systems, complex automation systems, welding solutions, exact positioning systems, automotive test machinery and a host of robot applications – from press shop, body shop and paint shop right through final assembly. Whatever the area of vehicle manufacturing, you can count on us for the ideal drive and control technologies as well as automation systems.

Expect unmatched know-how from us at every stage. Working with us, your business will benefit from true top-down and end-to-end integration of products and systems across the production plant. Whether you need precision controlled servo drives, innovative closed loop stepping system with drive, servo motors, brake motors, geared motors, variable speed solutions, inverter drives, rotary tables, actuators or HMIs, we’ll help you to automate your machines and plants flexibly and economically.

Get in touch with us and discover a new world of automation driven by innovation and engineered with know-how.

automotive / applications

This is where a car begins its journey. The car body first begins to take shape in the press shop as press panels. It’s where steel is uncoiled from steel coils, straightened, cut and stamped. Production lines are fully automatic with automatic tool changing. The challenge arises when the press panels have to be transferred to the body shop. This apart, some of the press shop processes, too, can be extremely challenging. But none of this poses a problem for us.

We can help you take your press shop production line firmly under control with our precision controlled servo drives for uncoiling and straightening steel rolls. We provide gearboxes for the overhead conveyors that move parts and equipment down the production line. And, our motors, brake motors, geared motors and variable speed solutions ensure fault-free material handling with precise coordination.

Or consider our automation and process visualisation solutions which ensure smooth communication between the controllers and drives with the plant-wide operator control and monitoring systems. Each step is executed quickly and precisely for the next process.